Atpresent, a new round of global scientific and technological revolution andindustrial transformation is in full swing, and information technology ischanging rapidly. Industrial software, as one of the important drivers, isgiving birth to a large number of new industries, new business forms and newmodels, accelerating the progress of China's new industrialization andinjecting new momentum into the global manufacturing industry.

LanyouTechnology made a stage pose at the 3rd China Industrial Software Conference

OnJune 20, the 3rd China Industrial Software Conference, sponsored by the SmartChina Expo Organizing Committee, the Ministry of Industry and InformationTechnology and Chongqing Municipal People's Government, was held in YuzhouState Guest Hotel, Chongqing, with the theme of "Software InnovatesManufacturing, Intelligence Connects Future". The Expo gathered officialsfrom ministries and government departments in charge of industrial software,representatives of upstream and downstream enterprises, big shots from theindustry, experts and scholars in the field of science and education, to carryout in-depth discussions and exchanges on hot topics such as development ofintelligent industrial software, enterprise digitalization and knowledgemanagement, and transformation to digital intelligence.

Mr.Hu Yongli, General Manager of Lanyou Technology, was invited to attend the mainforum of the conference and delivered a keynote speech on "IndustrialSoftware Innovation and Transformation to Meet the New Challenges of AutomotiveDigital Intelligence", sharing the new model of industrial softwareinnovation and business transformation under the development trend of digitalintelligence in the automotive industry.

Industrial softwaredrives industry transformation

Automotivemanufacturing is the pillar industry of industrial manufacturing in the pasthundred years. With the advent of the era of automotive digital intelligence,the traditional automotive industry is undergoing a huge change. Industrialsoftware is an inevitable choice in the era of Industry 4.0. According to therelevant research report, the overall software market size of China'smanufacturing industry will grow from 153.32 billion yuan to 336.14 billionyuan from 2021-2026, with a compound annual growth rate of 17%.

HuYongli analyzed the development trend of the automotive industry, and said that industrial software is an important driver of industry transformation. In light of the development trend of the automobile enterprises, Hu Yonglifurther noted that in the course of transformation to digital intelligence, theautomobile enterprises need to pay close attention to - as regards marketing,providing full-scenario product services, meeting customers’ customizationneeds and improving user experience by establishing connections with users viaall contact points; as to manufacturing, improving production efficiencyand reducing production costs by building intelligent plants; as to products,improving product competitiveness through rapid product iteration and onlineupgrades.

“Hotspots such as marketing, manufacturing and products that automobile enterprisesare concerned about are reflected in business change, which is actually aboutreconfiguring our capabilities around the users, products and factory operations.”Hu Yongli believed that in order to do a good job in the transformation ofautomobile enterprises to digital intelligence, we need to deal with threemajor challenges -

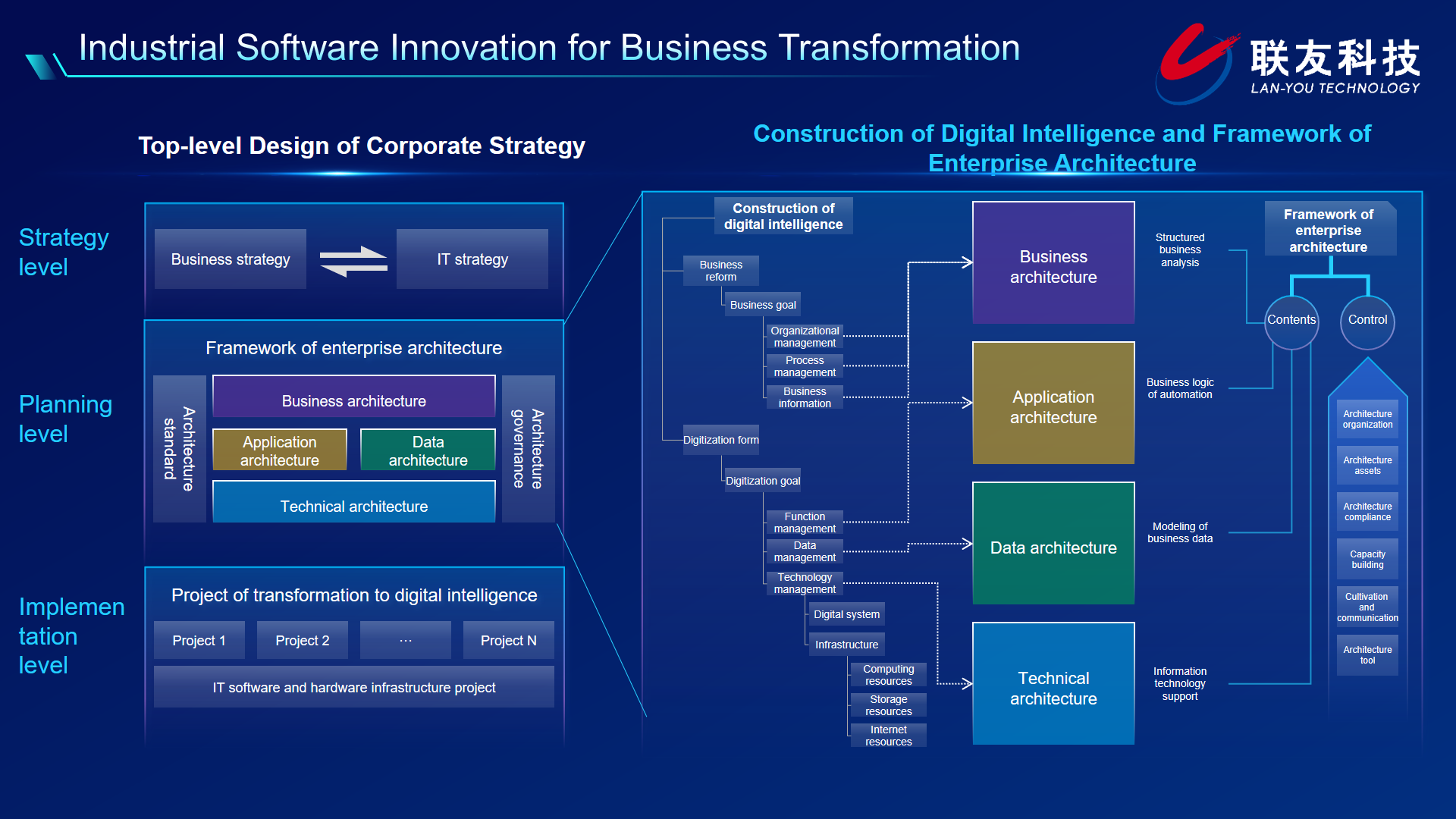

First,to form the "brain" of transformation, that is to focus on thetop-level design and avoid the "pilot trap" in the process oftransformation;

Second,to build the "skeleton" of transformation, that is to fully plan theenterprise architecture that supports business transformation;

Third,to circulate the "blood" of transformation, that is to fully"awaken" a large number of "dormant" data assets.

Industrialsoftware innovation for business transformation

Inpractical application, automobile enterprises draw a "reformblueprint" through top-level design, and then rapidly implement this"reform blueprint" with the help of enterprise architecture. Sincebusiness transformation and enterprise architecture are in a one-to-manyrelationship, the business transformation needs to be implemented through theenterprise architecture in the end.

Atthe business architecture level, in order to meet the diverse personalized needs, LanyouTechnology, with more than 20 years of experience in the manufacturing field,has established delicacy management capabilities in three aspects offlexibility, digitalization and intelligence around ten business scenarios,providing rapid support for the market. Starting from product purchase, theintegration of customer choice data and production configuration data isrealized through supporting customers’ participation in demand design; in theR&D and manufacturing stages, C2M customized production is realized throughorder-and-factory synergy, lean supply chain management, flexible productionline construction, and whole-process quality control and tracking. Eventually,all the information is displayed in real-time in the information center toassist production monitoring and intelligent decision-making.

Atthe product level,Lanyou Technology has designed the business and application architecture forthe whole process of intelligent manufacturing, covering the product chain,value chain and equipment asset chain, and established 2 management lines forthe whole value chain (cost management and total quality management) to supportthe continuous improvement of the business process. Ultimately, costmanagement, quality management and unified data management of the whole valuechain have been realized. In particular, in terms of data management, LanyouTechnology has realized the full connection among five types of data: productmaster data, process master data, material master data, manufacturing masterdata and service master data, hence unclogging the "data veins” to enablethe efficient flow of data.

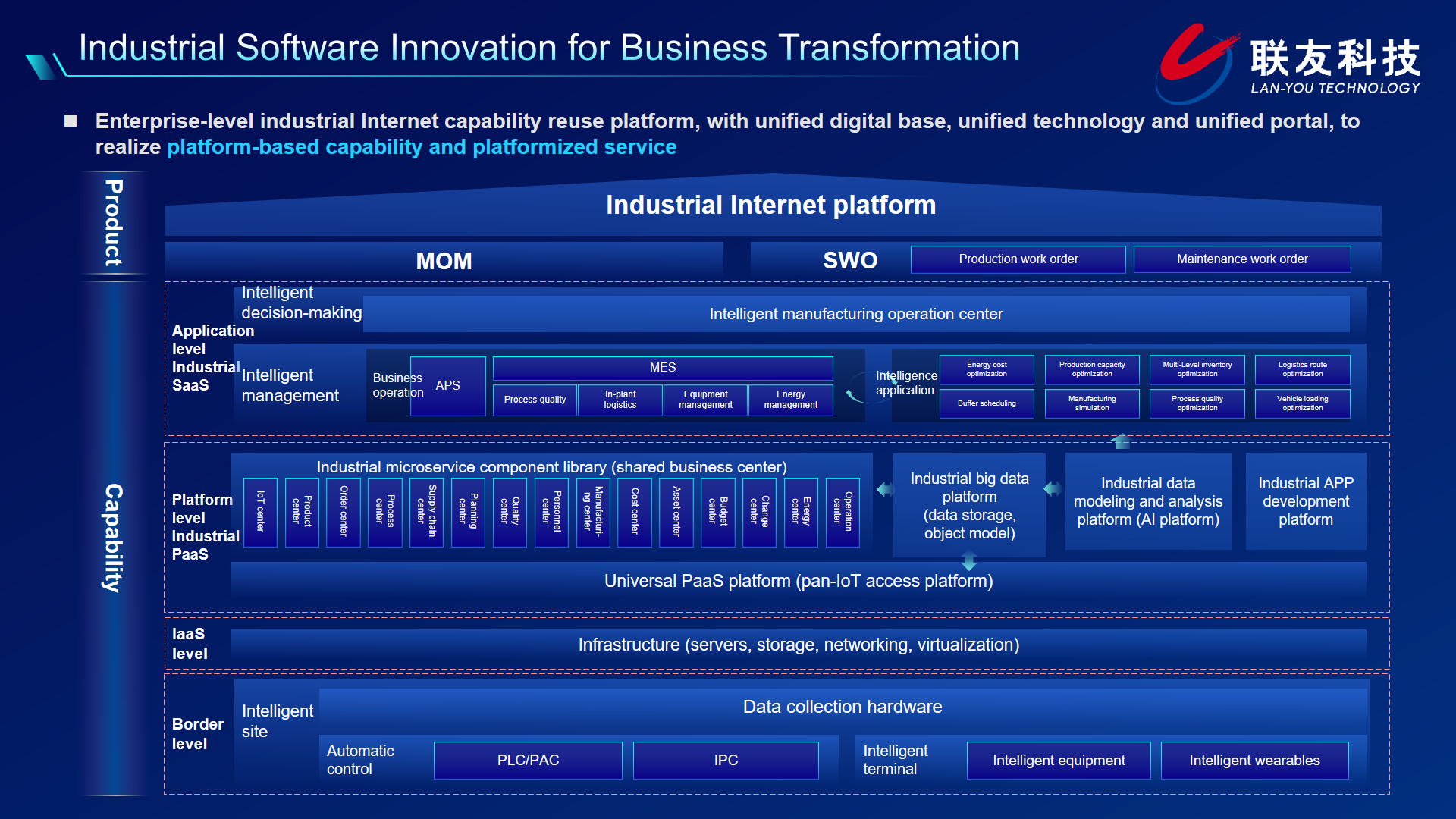

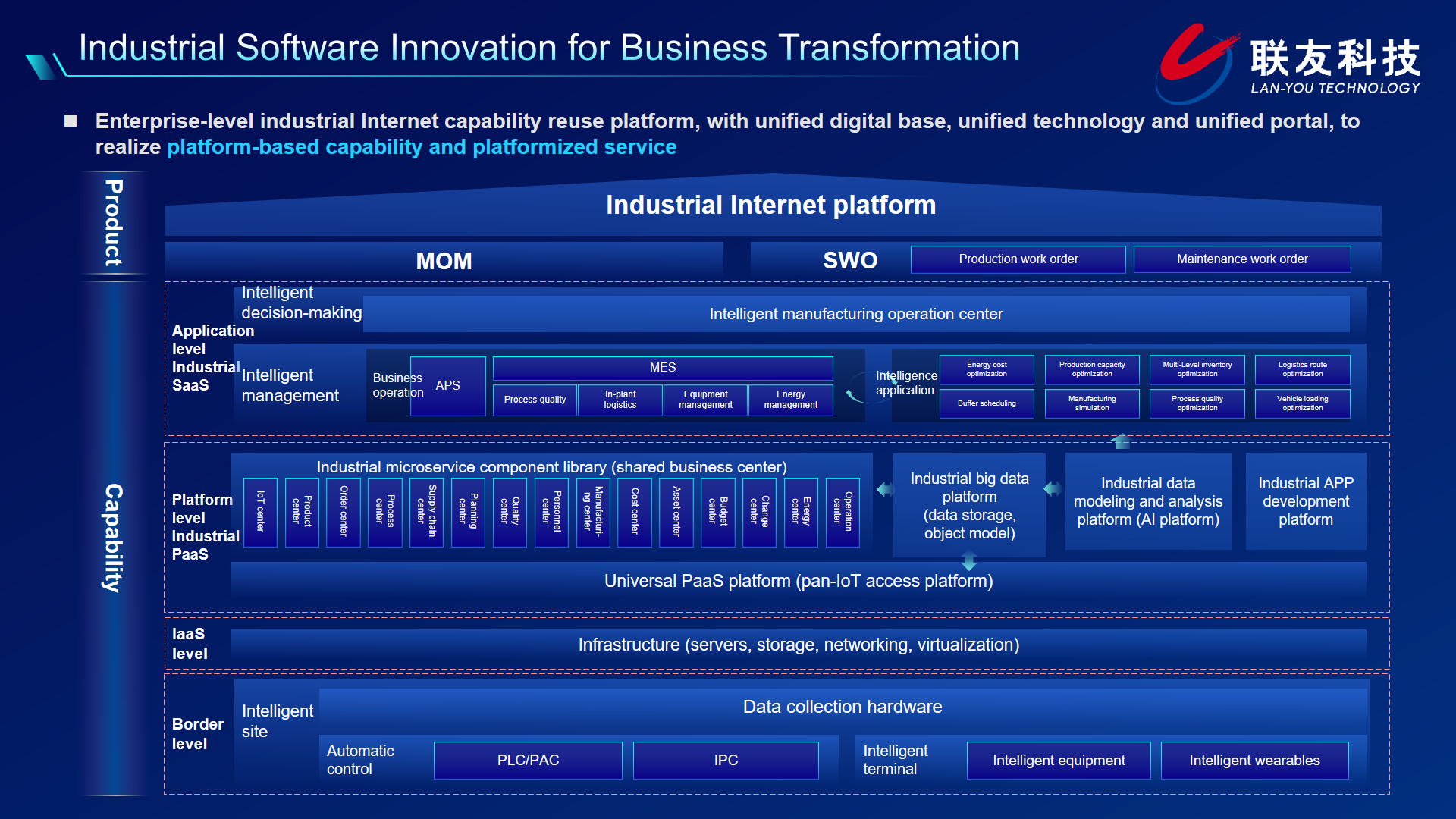

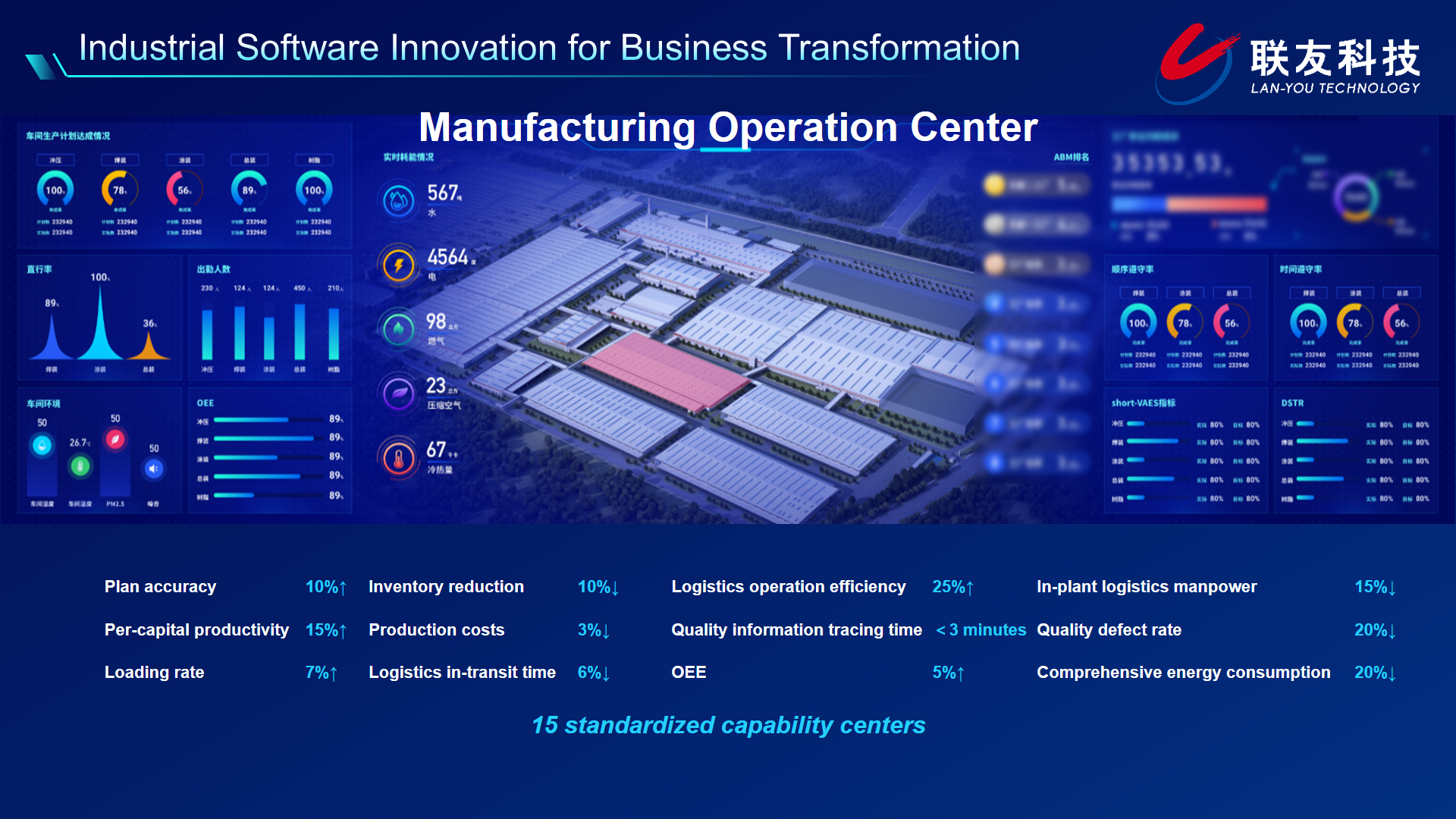

Atthe technical architecture level, Lanyou Technology has built a unified industrialInternet capability reuse platform to realize the platform-based capability andPaaS through a unified digital base, unified technology and unified portal. Onthe industrial Internet platform, through 15 standard shared business centers,intelligent decision-making and intelligent management of business are realizedto support the development of intelligent manufacturing business. Thistechnical architecture has been adopted by a number of automobile enterprises.

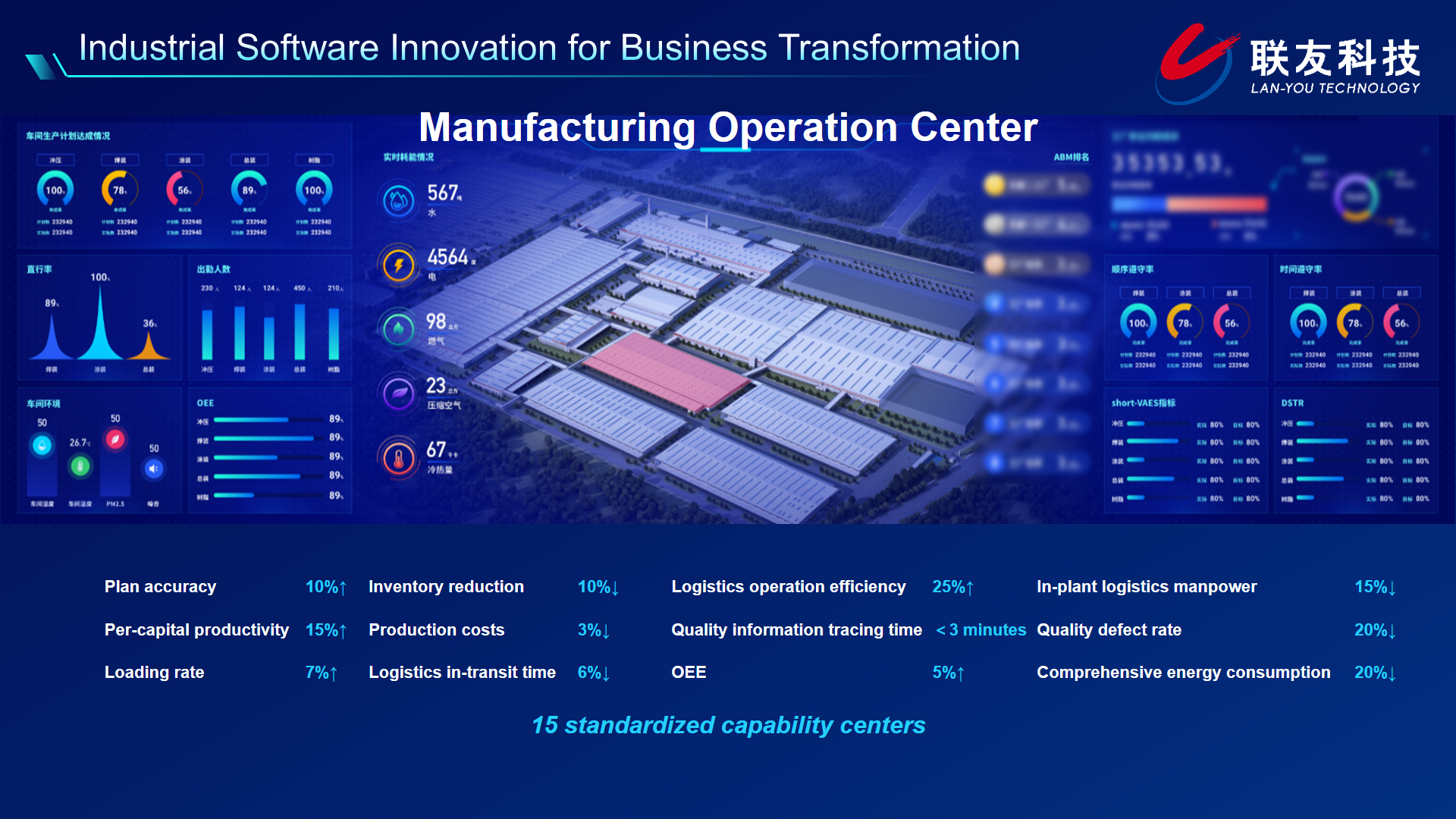

"Throughthe manufacturing operation center supported by 15 standard shared businesscenters, Lanyou Technology has helped automotive enterprises achieve overallimprovement in many aspects such as planning effectiveness, productionefficiency, production cost control, logistics efficiency, quality defectcontrol and overall equipment efficiency.” Regarding how the manufacturingoperation center can help with the transformation to "intelligent"manufacturing, Hu Yongli introduced that building a technical architecture thatprovides necessary support can help the automobile enterprises quickly meet theIT needs of new factory construction and old factory reconstruction, andachieve optimal cost and maximum sharing, enabling them to rapidly launch theirinnovative business Technical architecture and data architecture, which serveas “two cornerstones", have laid a digital foundation to support thefront-end to form closed-loop business, and provide guarantee for the rapiddevelopment and innovation of enterprises.

Unleashingthe value of data based on “business scenarios”

Howcan the data, which shoulders the mission of monitoring the market dynamics,give full play to its value? Hu Yongli introduced that as early as April 2020,China listed data as the 5th major production factor for the first time."Untapped data is like a pool of stagnant water, its own value has notbeen reflected, and only by making data flow can it become an asset.” The valueof data can only be unleashed and cashed in by operating the data properlybased on customers and products with the help of years of experience in digitalbusiness.

LanyouTechnology uses big data to drive changes in decision-making and productionmodels, and reshapes traditional value chain processes of the enterprisesthrough reuse of data assets and digitization technology, improving quality andefficiency of existing business. It gradually realizes intelligence based onvisibility, interconnection, prediction and self-adaptation and establishes newbusiness incubation and expansion mechanism to support enterprises to seizeopportunities and gain new growth points.

Regardingthe value of data, Lanyou Technology has nearly 170 digital applicationscenarios in the whole business chain of the automobile industry, including 36in the manufacturing field. Take the business scenario in terms of inventorycontrol in the manufacturing field as an example, through dynamic predictionalgorithms based on parts inventory data, Lanyou Technology has reduced about 2billion yuan worth of inventory for customers in a period of two or threeyears.

Relyingon 21 years of experience in automobile manufacturing, Lanyou Technology hasdeveloped the nationally leading digital service capability regardingintelligent manufacturing in the automobile industry, established awhole-process and all-scenario business chain that is customer value-orientedand covering from end to end, and developed a one-stop solution spanning fromplanning, design, implementation to delivery of whole plant. By focusing oncore scenarios, pinpointing pain points, and driving business throughtechnology, Lanyou Technology’s smart manufacturing solution will helpcustomers build more intelligent benchmark plants and forge a promising futurethrough digital intelligence!

智能制造

數(shù)字營銷

智能網(wǎng)聯(lián)平臺

數(shù)智金融

數(shù)字運營

數(shù)字運營數(shù)智技術(shù)

智能化產(chǎn)品

云服務(wù)

云服務(wù)