DongfengNissan, a well-known domestic car maker, has always been committed totechnological innovation and product upgrades. With rich experience and profoundtechnical expertise in the field of automotive manufacturing, Dongfeng Nissanconsistently provides consumers with high-quality, intelligent automotiveproducts and services.

Underthe theme of “Make Innovation, Increase Efficiency, and Embrace Intelligence”,Dongfeng Nissan’s Xiangyang and Zhengzhou factories hosted a technologyexhibition to showcase their innovative achievements. Lanyou Technology wasinvited to the event and demonstrated its cutting-edge visual recognitiontechnologies, gaining widespread attention from clients and guests.

Currently,the manufacturing industry is undergoing a profound transformation, withinformatization, digitalization, and intelligence becoming the focus and goalof manufacturing. The automotive manufacturing industry has always been at theforefront of technological innovation. In recent years, with the vibrantdevelopment of emerging technologies, the carmaking sector has begunintegrating AI into production processes, accelerating the transformation andupgrade of vehicle manufacturing.

ManualGluing Inspection Powered by AI Vision and Machine Vision

Ascar manufacturing technology and processes continue to improve, automobile gluingtechnology has become widely adopted by major automakers and componentmanufacturers. Automobile gluing serves multiple purposes, such as bondingsimilar or dissimilar materials on the vehicle body, optimizing productstructures, and even replacing some welding or riveting processes to enhancethe aesthetics of the vehicle while optimizing and simplifying productionprocesses. The quality of glue application directly affects the product qualityand driving safety of the vehicle. Therefore, gluing inspection is an essentialstep in the intelligent and automated production workshop of car manufacturers.

LanyouTechnology, combining AI vision with machine vision, proposes an intelligentgluing inspection solution. This solution utilizes AI algorithms to activelyintervene in quality control, achieving real-time inspection during production,convenient quality inspection, and efficient problem traceability. To accountfor variations in environmental lighting and materials in actual productionsettings, an adaptive AI algorithm is employed to dynamically adjust andoptimize imaging, addressing issues of inaccurate detection under variousinterference conditions and significantly improving the accuracy and efficiencyof product inspection.

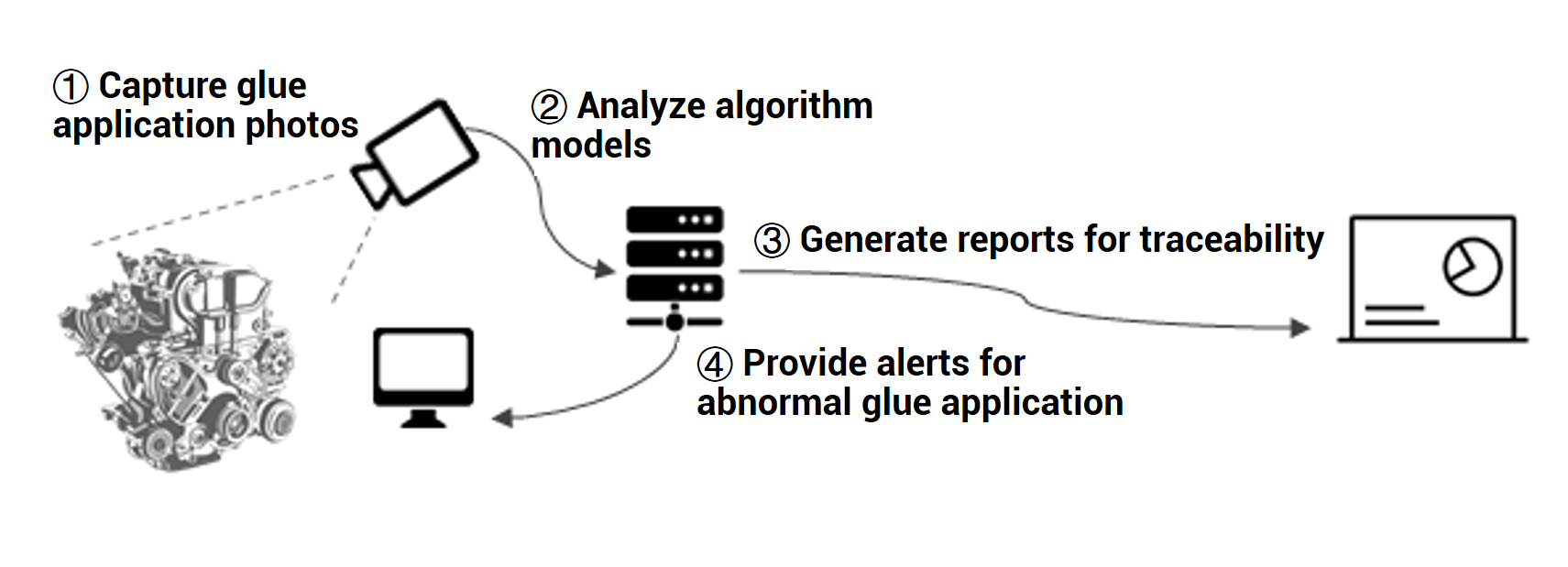

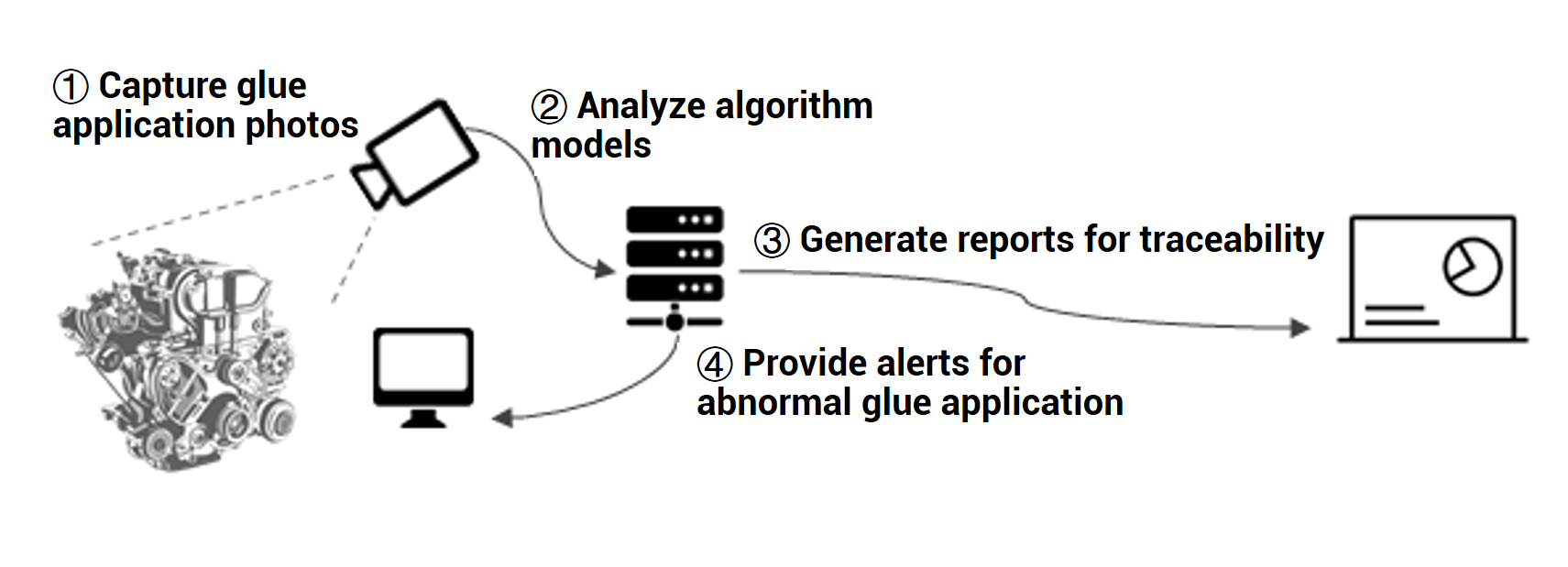

1. Capture glue applicationphotos: Utilize high-precision cameras and lighting to capture the glueapplication process on the industrial production line and extract valuableimage data.

2. Analyze algorithm models:Compare different algorithms in terms of precision, speed, and stability whenprocessing glue application photos, and select the most suitable model forpractical application requirements.

3. Generate reports fortraceability: Prepare reports on statistical data, imagecomparisons, and process monitoring, to help managers better understand thequality and efficiency of the glue application process and promptly identifyand resolve issues.

4. Provide alerts forabnormal glue application: Timely identify anomalies such as uneven applicationand interruptions through real-time monitoring of the gluing process, and issuealerts to facilitate prompt action by staff.

EffectiveResults

Eliminationof the outflow of defective products: Machine vision enables completequality inspections, allowing for timely remedies of quality defects andpreventing the outflow of defective products.

Problemtraceability in 1 minute: Historical glue application photos can be retrieved based on any defective product’sidentification number, enabling quick confirmation of any gluing qualityissues.

LanyouTechnology holds 21 years of experience in the automotive manufacturing sectorand provides leading digital services for the auto industry. With acustomer-oriented, end-to-end business chain encompassing all processes and scenarios,it offers one-stop solutions that cover planning, design, implementation, anddelivery. Leveraging AI visual recognition technology, Lanyou Technology hasconstructed flexible digital production workshops that emphasize core scenariosand accurately address pain points. This technology-driven solution has greatlyempowered businesses to make innovation and increase efficiency.

Intelligent manufacturing

Cloud Service

Digital enterprise resources

MarTech

Auto intelligent partsAuto smart networking

Auto smart cabin

Auto R&D

Auto R&D Auto smart driving

Auto smart driving