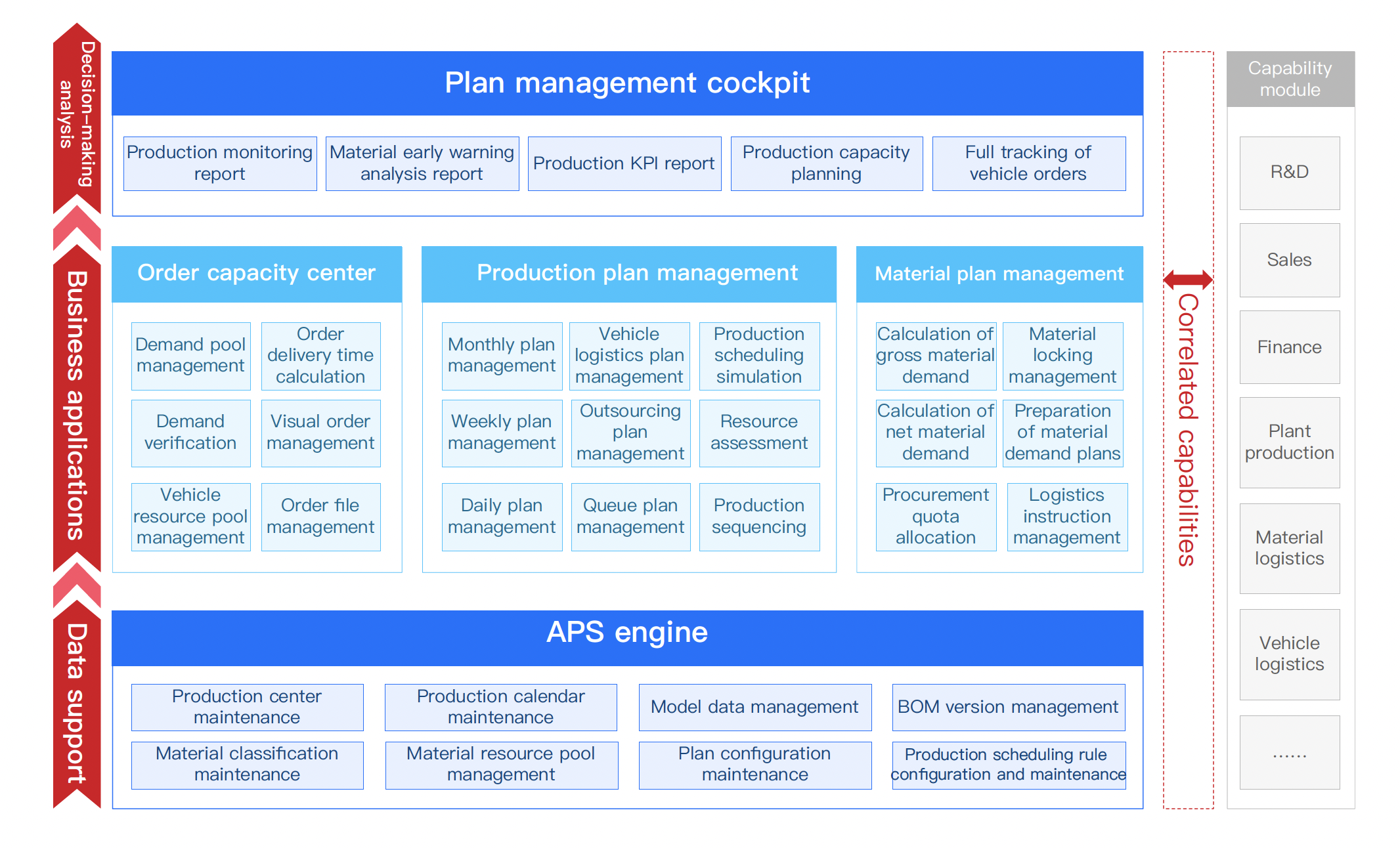

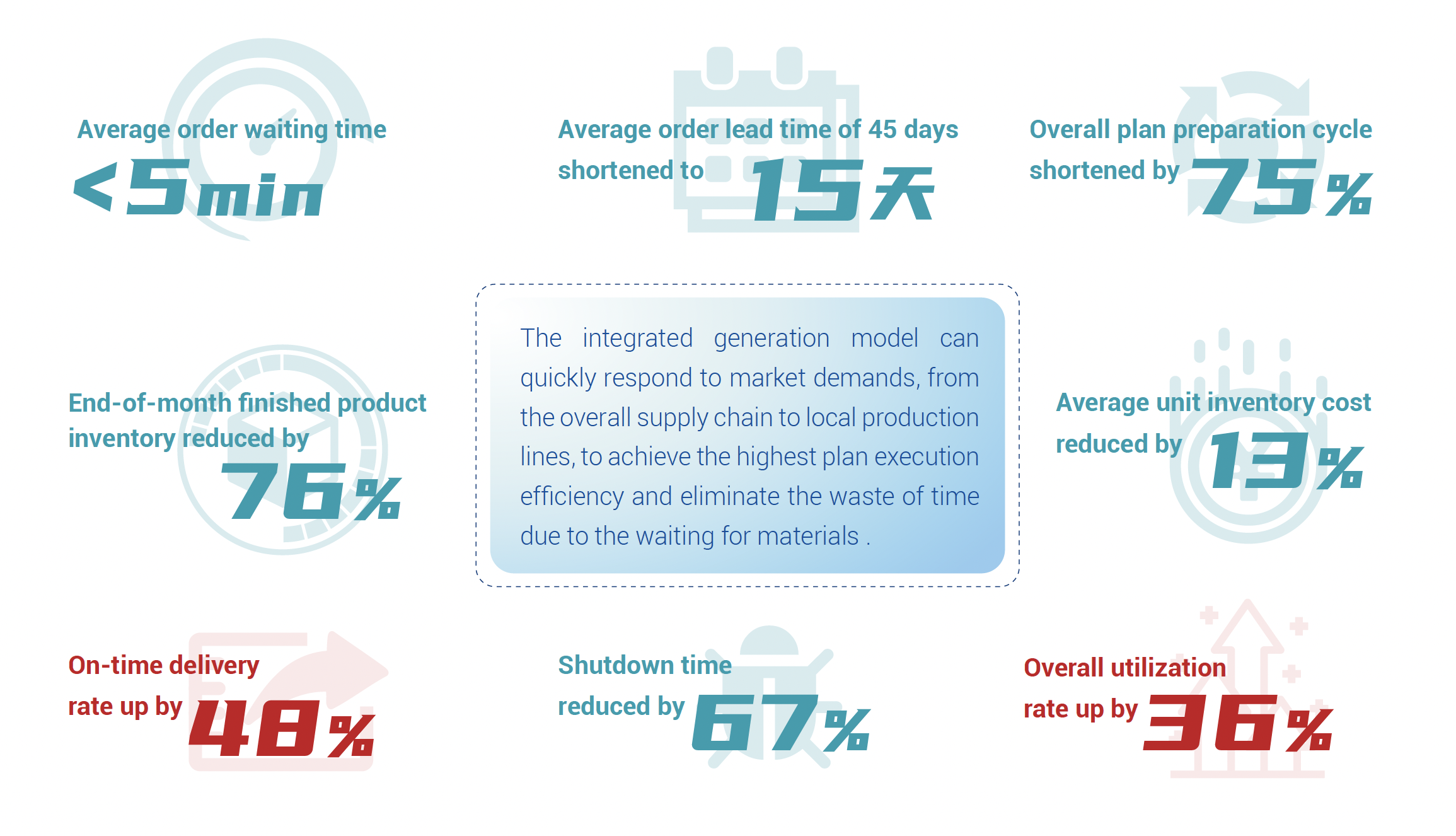

As an advanced production scheduling system and an optimization engine for smart plants, the Lanyou APS converges more than 20 years of dedicated research and successful implementation experience in the manufacturing field, encompassing functions such as order capability center, production plan management, logistics plan management, plan management cockpit and APS engine. It is a practical product for enterprises to achieve lean manufacturing, end-to-end controllable management, and digital transformation.

Intelligent manufacturing

Cloud Service

Digital enterprise resources

MarTech

Auto intelligent partsAuto smart networking

Auto smart cabin

Auto R&D

Auto R&D Auto smart driving

Auto smart driving